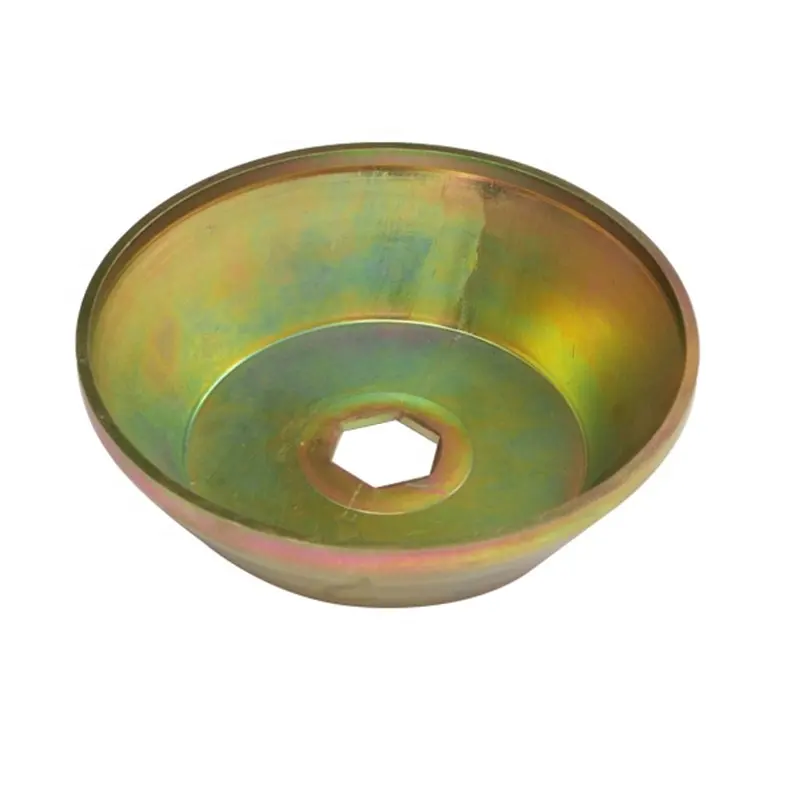

Custom Deep Drawn Metal Stamping is a manufacturing process that involves forming metal sheets into various shapes and sizes using a punch and die. This process is ideal for producing complex and intricate parts that require high precision and accuracy. Our team of experts can help you design and manufacture custom deep drawn metal stampings that meet your specific requirements. We use high-quality materials and advanced manufacturing techniques to ensure that our stampings are strong, durable, and reliable. Our customization options allow you to choose the perfect size, shape, and finish for your application. Whether you need stampings for automotive, aerospace, or medical industries, we can provide you with the perfect solution.

our full-service deep draw manufacturing capabilities

At our custom metal fabrication Factory, we offer full-service deep draw manufacturing capabilities that include trimming, piercing, and forming as secondary operations. In cases where volume is too low to justify tooling for these operations, we have the ability to trim and pierce using our advanced 5-axis laser cutting technology. This complementary equipment allows us to add openings of any shape in any location of a deep drawn part, providing greater production flexibility, reducing total capital investment for tooling, and significantly speeding up the production process. Trust us to deliver high-quality, cost-effective solutions for all your metal fabrication needs.

Which material can with Deep Drawn Metal Stamping?

When it comes to deep drawn metal stamping, the material used plays a crucial role in determining the success of the process. Generally, materials that have high ductility and malleability can withstand deeper draw in stamping. Some of the most commonly used materials for deep drawn metal stamping include stainless steel, aluminum, copper, and brass. These materials have excellent mechanical properties that make them ideal for producing complex shapes and designs with precision and accuracy. Additionally, they offer high strength, corrosion resistance, and durability, making them suitable for a wide range of applications in various industries. Ultimately, the choice of material depends on the specific requirements of the project, and a skilled metal stamping professional can help determine the best material for your needs.

The Benefits of Deep Drawn Stamping – Precision, Versatility, and Efficiency

Deep drawn stamping is a highly efficient and cost-effective manufacturing process that offers numerous benefits. One of the main advantages of deep drawn stamping is its ability to produce complex and intricate shapes with high precision and accuracy. This makes it an ideal choice for creating parts and components that require tight tolerances and intricate designs. Additionally, deep drawn stamping can be performed on a wide range of materials, including metals and alloys, allowing for greater flexibility and versatility in the manufacturing process. Other benefits of deep drawn stamping include improved strength and durability, reduced material waste, and faster production times. Overall, deep drawn stamping is an excellent choice for manufacturers looking to produce high-quality parts and components quickly and efficiently.

At ANK, we offer a wide range of custom deep drawn metal stamping solutions to meet your unique needs. Our extensive stamping capabilities allow us to produce high-quality components that are both durable and reliable. Whether you need small or large quantities, we can provide you with the custom metal stamping services you require. Contact us today to learn more about how we can help you with your most challenging metal stamping needs, or request a quote to get started.